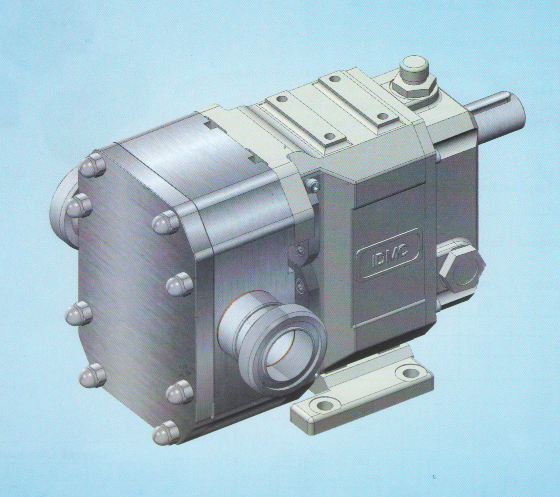

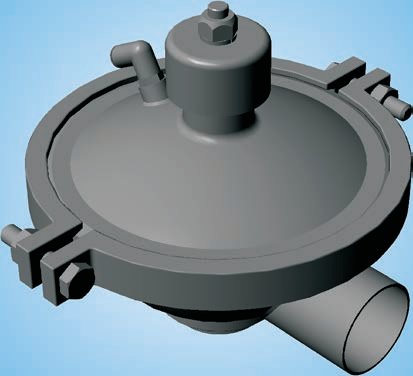

3 WAY FLOW DIVERTER SANITARY VALVE

Reliable product for continuous operating plants.

• Easy to operate and maintain.

• Flow divert valve available with various orientations such as LL, LT, TL and TT types as shown in pictures below.

• Designed for direct welding into sanitary piping system.

• Designed for smooth passage of the product with minimum pressure drop across the valve.

• Hygienic design suitable for Cleaning-In-Place (CIP).

• Available for automatic operation with pneumatic actuator from SMS 25 up to SMS 101 sizes.

• The actuator can be equipped with IDMC control head for standard 24 V DC operation or ASi field-bus actuation.

• Control heads are available in two versions 'Economic' and 'Advance'.

• Valve control head LEDs indicate its working position visible from a distance.

• Available variants of valve body connections like Plain End and Weldable Union End.

• Actuators are double acting equipped with a spring.

• Available in Normally Closed (NC) and Normally Open (NO) configuration

• Size : SMS 25 up to SMS 101 (from pipe OD 1” up to 4“ suitable for ASTM A270)

• Product wetted steel parts : SS 316 L or SS 304

• Other steel parts : SS 304

• Product contact Gaskets/Seals : EPDM (suitable to US FDA 21 CFR 177.2600)

: Up to 10 bar with NC configuration

: 2°C to 125°C

he function of the Shut-off valve is to shut-off the flow in the line.

• The function of the Flow divert valve is to change over in process liquid flow in pipelines.

• Operation of Pneumatic Seat Valve takes place by means of pneumatic actuator.

• Double acting actuator enables the valve to reset with combination of air and spring force.

• Valves can be operated by pneumatic actuator from SMS 25 up to SMS 101.

- Pneumatic actuator air pressure: 5 bar (minimum)

- Pneumatic actuator air pressure: 8 bar (maximum)

(Here Is The Product's Brochure Pdf File.)

Submit Inquiry